News

Merry Christmas 2023

At the end of the year, we look back on a year with major challenges for society. The transformation of energy conversion and the increasing focus on saving resources combined with the desire to maintain prosperity offers us all great opportunities.

We are happy to accompany our business partners on this exciting path and look forward to new questions in the field of plastics testing.

We wish our customers, suppliers and friends of the company a peaceful Christmas and a healthy start into the new year 2024.

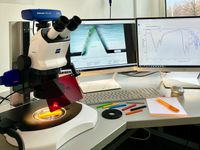

Modernization of microscopy

In November 2023 we modernized the microscopy workplace.

The workplace is primarily used for the light microscopic preparation of particles for our infrared spectroscopy. The particles we analyze range in size from a few micrometers to a few millimeters. Depending on the delivery condition, we have to prepare, divide or reshape the particles before infrared spectroscopic analysis. In addition to good magnification, a variety of lighting modes from the side, above or below are required to clearly see the particles during preparation.

In addition, the workplace is also used for the geometric measurement of testing equipment such as: needles of the Vicat testing device or notches made in test specimens.

The new light microscope from company Zeiss is equipped with a modern digital camera that enables all work steps to be documented.

testXpo - International Expo for Materials Testing

In October 2023, the International Expo for Materials Testing will take place for the 31st time at ZwickRoell in Ulm-Einsingen.

ZwickRoell, as the leading manufacturer of materials testing technology, is presenting new developments in the field of testing technology for research, development and quality assurance together with 20 co-exhibitors. In particular, testing solutions for new drives such as Hydrogen technology shown.

We are present as co-exhibitors. Come to Ulm and we will be happy to discuss current issues surrounding the testing of plastics with you.

Modernization of hardness measurement

In the summer of 2023, we modernized the testing station for determining ball indentation hardness in accordance with ISO 2039 Part 1.

The testing device used previously consisted of a stiff testing frame and was based on the applying of fixed weights that exerted a force on the surface of the test specimen and thus caused the spherical impression on its surface. The different test loads described in the test standard were implemented with four different weights, which had to be placed in the test device by the laboratory technician. A proven method.

However, developments on the testing equipment market are progressing. The company EMCO-TEST from Austria - a member of the ZwickRoell group - has developed a state-of-the-art testing device with the DuraJet G5 testing device. It also has a highly rigid frame. However, the force on the surface of the test specimen is no longer realized by weights, but rather by a motor drive and an intermediate load cell. This monitors whether the force applied within the test period meets the normative requirements.

The advantage of this testing device is that the selection of the testing force no longer has to be done manually. The control electronics and software fully monitor the entire testing process. In addition, there is no need to handle weights weighing up to 7.5 kg. The testing device received top marks in international round robin tests in which we regularly participate and in our internal quality routine. The efficiency and occupational safety of the testing device has already proven itself in everyday testing.

Merry Christmas 2022

At the end of the year, we would like to thank our business partners for the trusting cooperation and look forward to exciting new projects in the coming year.

We wish our customers, suppliers and friends of the lab a peaceful Christmas and a healthy start into the New Year 2023.

polymerphys IK has switched mobility to electricity

Mobility is important for the employees at the Frankfurt site during the working day. Above all, it serves to promptly transport the test specimens from the customer to the testing lab. However, it is also necessary in order to reconcile the working hours with the care times for the family offspring. Unfortunately, public transport does not yet offer the necessary flexibility to present an alternative offer.

polymerphys IK actively supports the transformation of mobility from combustion engines to electric drives.

The main reason for this is the large reduction in the energy required for driving. While the previously used vehicles with combustion engines had an average consumption of 6 liters of petrol / 100 km, the consumption of the new electric vehicles is 10 kWh of electricity / 100 km. The energy content of fuel is around 9 kWh / liter. This means that the electric vehicles are driven with an energy equivalent of around 1.1 liters of fuel / 100 km. There is currently no vehicle with a combustion engine that uses the energy it carries so efficiently.

The argument of the short range at higher speed and the associated higher power consumption is due to the currently still low storage capacity of the vehicle batteries. Converted into energy equivalents, the batteries in the new electric vehicles correspond to a tank capacity of 3 to 4 liters of fuel. In city traffic, the electric vehicles are driven around 300 km before they are recharged. A vehicle with a combustion engine would only be able to cover a distance of around 70 km with such a small tank capacity.

The relatively small storage capacity means that the vehicles must have a low mass. The new vehicles weigh between 1.2 and 1.3 tons, making them ideal for city traffic. They also have compact external dimensions, but with four doors they can also be used flexibly in everyday family life.

testXpo - trade fair for testing technology

In October 2022, the trade fair for testing technology will take place again at ZwickRoell in Ulm.

The leading manufacturer of material testing technology presents the new developments in the field of testing technology for research, development and quality assurance together with 20 co-exhibitors.

We invite you as a co-exhibitor. Visit testXpo, find out about the current status and trends in materials testing.

Historical Museum Frankfurt goes mobile

The Frankfurt Historical Museum has had a new transport vehicle since July 2022. This is required to transport the exhibits between the various locations and to exhibitions.

70 companies from the Frankfurt area have joined forces to make the procurement of this vehicle possible.

Each sponsor may indicate their support with a sticker and thus also advertise themselves. After all, the vehicle drives regularly on Frankfurt's streets. You might see the vehicle with the registration number F-HM 1878 (this is the year the Historical Museum was founded) somewhere near you. Keep an eye out!

Recycling tested specimens

The specimens shown in the four boxes are the result of three weeks of "breaking down".

Around 50,000 specimens with a mass of around 700 kg are tested at polymerphys IK every year.

In the past, the test specimens were sent for thermal recycling. In this process, fossil fuels such as oil and gas to be used in the incineration plants can be saved, since the plastics, as exothermic substances, actively support the incineration process.

However, there are now ecologically better processes to continue using the high-quality plastics.

The test specimens are sorted and sent for material recycling. We either use existing recycling processes of our customers or we develop corresponding processes together with our customers.

Modernization of fiber length analysis

The fiber length analysis is an important test method that is used primarily where long-fiber-reinforced thermoplastics are processed by injection molding. Only optimized processing ensures that the performance of these materials can be fully exploited.

polymerphys IK has more than 20 years of experience with this test method. The first analyzes during the new development of this material were carried out almost manually with the help of light microscopy.

The use of the most modern microscopic and photographic hardware as well as the use of increasingly modern software today enables a real-time analysis of several thousand fibers from a component.

In March 2022, the workplace was equipped with the newly developed 4th generation FASEP.

Fair Interplastica in Moscow

polymerphys IK is a participant of the Interplastica exhibition in Moscow in January 2022.

Interplastica is the largest media event in the polymer sector in Russia with over 600 exhibitors and more than 20,000 visitors.

Here we present our range of services in the fields of plastics testing and proficiency testing.

Merry Christmas 2021

At the end of the year, we would like to thank our business partners for the trusting cooperation and look forward to exciting new projects in the coming year.

We wish our customers, suppliers and friends of the lab a peaceful Christmas and a healthy start into the New Year 2022.

At the Frankfurt location we look forward to a few relaxing days and say goodbye to our Christmas tree :)

And at the Nizhni Novgorod location, we look forward to the fact that the New Year tree is set up and decorated :)

Sales activity for DRRR in Russia

We have been cooperating with DRRR for several years in the field of quality assurance.

DRRR - Deutsches Referenzbüro für Ringversuche und Referenzmaterialien GmbH based in Kempten is a leading and accredited provider of proficiency testing and certified reference materials.

For a test laboratory, proficiency testing represent an important quality component in the independent assessment of competence and performance. Laboratories continuously check their own quality level with reference materials.

We take part in the international proficiency testing program organized by DRRR every year with selected test methods. The results are an independent, neutral testimony to our performance.

DRRR in turn commissions us to determine mechanical properties on the proficiency testing and reference materials used by DRRR in order to be able to make statistical statements about the materials.

We are pleased that we are expanding our existing cooperation with DRRR on August 1st, 2021.

Our Russian laboratory in Nizhny Novgorod takes over the distribution of the DRRR product range on the Russian market. PolymerPhysik Russia LLC is the first point of contact for test laboratories on the Russian market that want to prove their competence and performance in an international laboratory environment.

In addition to the administrative processing, we advise on all aspects of the range of products offered and are also available for technical support.

testXpo - this year again - the 29.

The testXpo trade fair for testing technology will again take place at ZwickRoell in Ulm from October 11th to 14th, 2021.

Together with more than 20 co-exhibitors, ZwickRoell will present the latest developments in the field of materials testing, specifically hardware, digitization and automation.

We are co-exhibitor and invite you to enter into a dialogue with us about our range of services in plastics testing.

Further information on registration can be found at this link.

Diversity - our point of view

Look at the colors of these granules. They form the basis for an endless variety of parts. We see this diversity and live and work with it every day as a matter of course.

We enjoy the rainbow and its millions of colors caused by the rules of physics. Physics applies everywhere and cannot be switched off.

In the same way, we also recognize and appreciate the diversity of people in their languages, education, values and feelings. We firmly believe in the diversity of nature and contradict every restriction.

Therefore we support all people, to #beyourself and invite everyone to follow us on this path.

Fair Rosmold / Rosplast in Moscow

After a long break due to the pandemic, we are resuming our active participation in exhibitions.

On June 15-17, 2021, Moscow will host the first major exhibition in the field of plastics and polymers Rosmold / Rosplast after a 2-year break.

polymerphys IK will take part in it together with its partners at stand 2C08 in Pavilion 2.

On the second day of the exhibition, we will participate in a" Round Table" together with other experts in the field of plastics. As part of the round table, you can ask the most relevant questions about plastic testing.

Further information please follow the Link:

https://rosmould.ru.messefrankfurt.com/moscow/en.html

New equipment for Fogging test

After successful reaccreditation we have the accreditation certificate according to ISO / IEC 17025:2018

We got the updated accreditation certificate, which confirms that our company and laboratory processes meet the requirements of DIN EN ISO / IEC 17025:2018. All details can be found on the Quality page.

polymerphys IK conducts workshop in the SIBUR PolyLab

On December 18-19, 2019, polymerphys IK held a practical workshop on the specifics of polymer mechanical testing. The event was held at the SIBUR Polylab site in SKOLKOVO, Moscow, Russia. Students from several production companies received certificates of successful completion of the training.

polymerphys IK is present at the testXpo

From 14 to 17 October 2019, the 28th testxpo trade fair for testing technology take place at ZwickRoell in Ulm.

Together with 25 co-exhibitors ZwickRoell presents the latest news in the field of material testing. Machine technology, Software, data processing, quality management are the topics that visitors can discuss with specialists from ZwickRoell and the co-exhibitors.

Practical test procedures are demonstrated on a variety of exhibits. Specialist lectures complete the scope of the event.

We present ourselves with our new mobile testing machine MobiZwicki. In addition, we explain in two lectures the possibility of analyzing fiber lengths in structural components.

We look forward to your visit.

polymerphys IK GmbH is 10 years old

On July 26th, 2017 polymerphys IK GmbH celebrated its 10th anniversary with business friends.

polymerphys IK is expanding its involvement in Russia